Dr.Jass

Pastor of Muppets

Research. Read. Research further. Study. Comprehend. Form a plan, and make preparations to execute it.

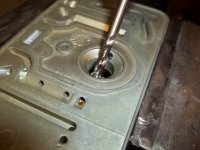

Then order a bunch of parts that--completely coincidentally--completely usurp the need to use any of the $200+ worth of other parts and tools you bought to execute the aforementioned plan. See the "eBay Holley" thread for details, but the new metering blocks and base plate are configured nearly perfectly out of their boxes. Well, I guess I'm ready for any future battles.

That's essentially where I am right now. I'm fairly certain that once assembled, the 9381 idle-mixture screws will work as intended, and cruise AFR will be within acceptable tolerances. The idle will probably be confirmed yet this year, but cruise appears to be out of the question until spring. We've already had a bunch of snow fall--not a lot of accumulation, but there's no going back now--and with daylight diminishing so early I likely won't get much further than straightening out the idle and putting Agnes to sleep for the winter.

Then order a bunch of parts that--completely coincidentally--completely usurp the need to use any of the $200+ worth of other parts and tools you bought to execute the aforementioned plan. See the "eBay Holley" thread for details, but the new metering blocks and base plate are configured nearly perfectly out of their boxes. Well, I guess I'm ready for any future battles.

That's essentially where I am right now. I'm fairly certain that once assembled, the 9381 idle-mixture screws will work as intended, and cruise AFR will be within acceptable tolerances. The idle will probably be confirmed yet this year, but cruise appears to be out of the question until spring. We've already had a bunch of snow fall--not a lot of accumulation, but there's no going back now--and with daylight diminishing so early I likely won't get much further than straightening out the idle and putting Agnes to sleep for the winter.