b-body-bob

Well-known member

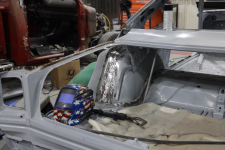

Road Runner out of the blast booth and headed to primer! This thing is solid.

The inner quarter panel there on the passenger side is just held in with Clecos. I guess they've noticed that by now - or not. I finished welding in the other side after I was finished with the outer wheelwell. Somebody thought it was a good weight saving idea to cut those out.