TheIronSausage

Two brain cells left.. rubbing together for warmth

What's the new ratio, and will it get out of it's own way as a result?

1st gear is so low in the first place. With the fresh rebuild I'm sure the torque avalible will be much better than it was before the up grade. Also, this is a quite common change from what I understand. I'm thinking the mechanical drum brakes will be more of an issue than the starting off will be.

Drill the drums and backing plates like I did.. I'm sure that guy'd love his restoration to have some 1940's style hot rodded drum brakes. It really does work great. I'll pretty much never pay the money for a disc swap again. If I gave you my Valiant and my Dart to drive normally in traffic, you'd be hard pressed to tell me which one had 9" drums all the way around, and which had the discs off of a Duster. I've got a Kelsey Hayes setup to go on the Valiant when I put the V8 in the Dart along with the Valiant's BBP suspension, but I don't plan on converting drum cars after that.

So, this is where I get questionable stares and people either think I'm an idiot, or tell me I'm a hazard to myself and others.. I drill the shit out of my backing plates and drums to ventilate my brakes.

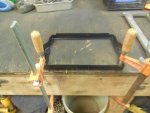

Here's how it works. Around the perimeter of the backing plate, drill a bunch (40 or so?) of #1 holes in the groove where the surface of the shoe lives. Then hog out the adjuster holes on the bottom of the backing plate to as large as you're comfortable with.. I did mine with a carbide reamer in a die grinder. Please ignore the shoddy spacing around the plate, and funny shaped holes in the bottom.. Not normally my style, but I had a cracked rib when I did this, and coughing felt like somebody stabbing me, let alone using a slide hammer. These were done on the car.

Then, (and this is where people freak out) drill your drums in a spiral pattern so that as much of the face of the shoe gets wiped by the holes as possible (drums are at least 3/8" thick.. They're fine). That is to say, imagine a straight line of holes from the front of the drum to the back. Leave the first where it is, move the second to the next hour on the clock, the third to the one after that and so on around the circumference so they're evenly spread out around the drum.

What this does, is basically turn the drum into a centrifugal air pump. Water, heat, and brake dust get ejected from the drum as the wheels turn. I've done this to a couple of cars now, and I've been able to drive through mountains, sit in stop and go DC traffic, drive through bad rainstorms and puddles all without brake fade or soaking problems.. As an added bonus, the inside of the brakes stay nice and clean, so there's no servicing, or unsticking of the star wheel necessary except shoe replacement and whatever adjusting needs to be done. It's worth mentioning that I drive my cars very hard. I typically brake harder and later into corners, and try to carry speed through, because everything I drive is such a slug, and because it's fun, dammit.

The only disadvantage I've found, is that you can't turn the drums after the modification. At least, I haven't tried..