Putting the bumpers on and I think I need a tip or two.

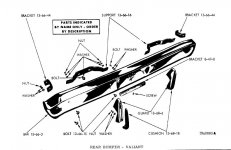

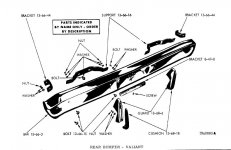

The bumper has 4 brackets. Two main brackets on either side of the license plate, that bolt to the rear crossmember, and two small C-shaped brackets in the corners that bolt up inside the trunk. I bolted them all to the bumper, and noticed that the small C-shaped brackets can move side to side and rotate, since they only have one bolt in a slotted hole. So, pretty much anywhere I bolt them to the bumper is a guess at best. It doesn't look like I can bolt them to the bumper after the fact either.

So yeah, if you have any ideas about how to install the thing, I'd sure appreciate it.

FWIW, it's not in the factory chassis, and I only found an illustration of the parts in the parts book that showed me how the brackets are oriented. I found a link to a pdf of the body manual in a post on FABO, and thought that should cover it, but all that did was take me to a highjacked A-body Joe website. and send my virus scanner into overdrive. I also tried using the wayback machine on the URL to find it, with no joy.

I searched multiple times over multiple days and not once did I find an explanation of how to do it. I finally decided that the brackets must bolt to the bumper first, because I could not find a single photo of a Duster with the brackets bolted to the body and the bumper off. It's like trying to find out the secret handshake of the Freemasons.